Download this manual

INTRODUCTION #

Dear Hydraloop Customer,

We’re excited to learn that you’re embracing the efficiency of using water twice with Hydraloop. To ensure a seamless experience, let’s confirm that your building is ‘Recycle Ready.’ This guide provides you with the necessary information.

Preparing a building for greywater recycling is straightforward. Essentially, you’ll need to add some extra piping to and from the Hydraloop device, along with ensuring proper ventilation, power supply and Wi-Fi or ethernet access. Looking ahead, new builds worldwide will be designed and constructed with ‘Recycle Ready’ capabilities in mind. Thank you for taking this eco-friendly step with Hydraloop.

Owner Guidelines #

This section of the Recycle Ready Guide is crucial for both the Hydraloop installer and the device user. Please review the Owner Guidelines and sign the Recycle Ready Checklist once all preparations are completed.

Plumbing & Installation Guidelines #

The second part of the Recycle Ready Guide provides essential information for the plumber or contractor responsible for preparing the building’s infrastructure. Before the work starts, it is imperative that all parties involved thoroughly understand both the Plumbing & Installation Guidelines. Once preparations are complete, both the device owner and the plumber or contractor who prepared the building for greywater recycling co-sign the Recycle Ready Checklist and forward it to Hydraloop Partner for verification.

Water Lines Before Installation #

Once the building attains ‘Recycle Ready’ status, the water lines will function through a temporary bridge connection, regardless of whether the Hydraloop device is installed. On the scheduled installation date, your Hydraloop installer will remove the bridge connection, place the device at the agreed-upon location, and establish connections to and from the device

OWNER GUIDELINES #

Work with professionals

The preparation of your plumbing network should be completed by a verified professional.

Check your local regulations

Before moving forward with your installation, please check your local guidelines for recycled greywater reuse.

Submit your Recycle Ready Checklist before installation

Before the installation of your Hydraloop device, it is important to ensure the building is Recycle Ready. Together with your plumber or constructor, co-sign the Recycle Ready Checklist and forward it to your Hydraloop Partner for verification. If you do not submit the checklist in time, we cannot verify, and therefore cannot proceed with the installation.

Ask if your Hydraloop installer has a viable HDM login

On the agreed installation date, your Hydraloop installer must have a prearranged login for the Hydraloop Device Manager (HDM) with a Hydraloop Sales Engineer. Without this access, activation of the device cannot be performed.

PLUMBING & INSTALLATION GUIDELINES #

Size and Location #

Location

Hydraloop recommends installing the device in a mechanical or technical room, basement, garage, or a laundry room.

Sound

A Hydraloop device is operational 24/7, collecting, treating, and redistributing water.

The distribution of reusable water via a distribution pump will produce a low decibel sound.

Temperature

The room temperature should be between 14–40˚C | 57–104 ˚F.

Sunlight

Avoid direct sunlight on the Hydraloop device. It is not IP rated or UV resistant.

Greywater Inlet

The greywater inlet and inlet diverter should be positioned at least 2.2 m | 87” above the ground.

Service space

Allow at least 70 cm | 28” of space in front of the Hydraloop device face plate for maintenance access. A H300 device will typically be placed against a wall. A H600 device has two sides (left and right) that should both be accessible for maintenance.

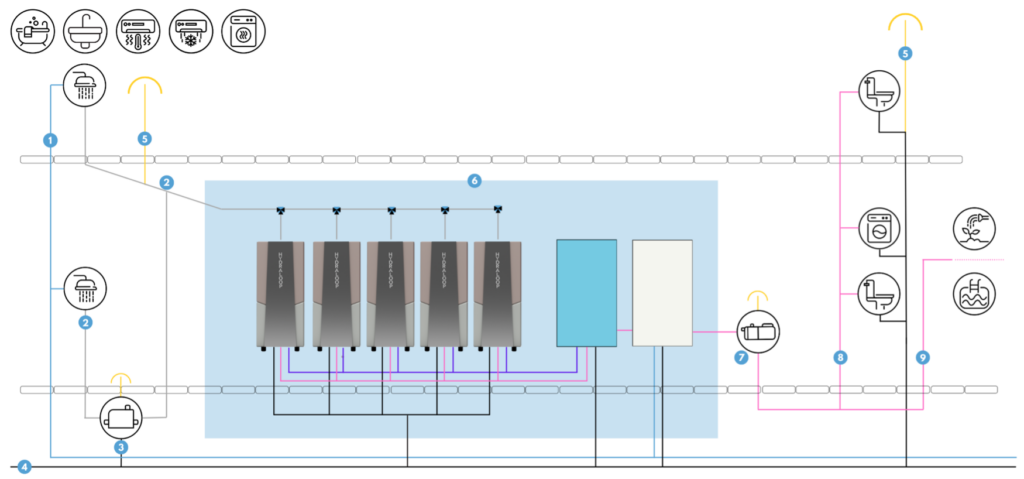

Recycle Ready Plumbing Diagram – Cascade and Polisher #

| 1 | Greywater supply from a higher floor shower, bath, hand basin, and/or condensation water supply from tumble dryer, air conditioning and heat pump. |

| 2 | Greywater supply from the same floor shower, bath, hand basin, and/or condensation water supply from tumble dryer, air conditioning and heat pump. |

| 3 | Lift pump (optional) |

| 4 | Sewer |

| 5 | Ventilation |

| 6 | Area and plumbing for Hydraloop Cascade and Polisher, managed by Hydraloop installer |

| 7 | Booster pump (optional) |

| 8 | Dedicated pipelines for reusable water output for toilet flushing and washing machine (pressurized). |

| 9 | Dedicated pipelines for reusable water output for topping up swimming pools and garden irrigation (non-pressurized). |

#

Plumbing Options #

Hydraloop device on a lower floor – input by gravity

Greywater from the shower/bath or other sources is gravity fed into the Hydraloop device.

Hydraloop device on the same floor – input via lift pump

Greywater from the shower/bath or other sources enters the device through lift pump.

Plumbing Guidelines #

Input Connections

For H300: Only collect lightly contaminated greywater from shower/bath and washing machine (with optional inlet diverter). Do not connect the Hydraloop device to dishwashers, floor drains, or a kitchen sink.

For H600: Only collect lightly contaminated greywater from shower/bath and washing machine (with optional inlet diverter) and condensation water from air conditioning, heat pump, and tumble dryer. Do not connect the Hydraloop device to dishwashers, floor drains, or a kitchen sink.

Output Connections

Reusable water can be used for toilet flushing, washing machine and/or distributed via an auxiliary outlet (for garden irrigation or pool top-up). Do not supply bidets and/or hand showers with reusable water.

Non Potable Water Identification

All outputs from the Hydraloop system must be identified with a non-potable water sign.

Power/Network Requirements #

Ensure there is a power outlet or junction box within 1.2 meter | 47“ of the top of each Hydraloop device, as it operates on a 100-120V (60Hz) or 200-240V (60Hz) power supply.

Each Hydraloop device requires a stable internet connection via a stable Ethernet connection or a WiFi network that supports 2.4 GHz frequencies. A reliable internet connection is crucial for tracking the water treatment process and proactively monitoring device functionality.

Extraordinary Situations #

Operation during power outage

Hydraloop devices operate seamlessly using a standard wall outlet. During a power outage, the device automatically switches to its backup batteries to safely drain the tanks, preventing any potential overflow. However, it’s important to note that during a power loss, the device won’t be able to supply water to toilets and/or the washing machine. To ensure continuous water availability, we recommend considering the following backup options:

- UPS (Uninterruptible Power Supply): Invest in a UPS to provide temporary power and maintain the Hydraloop’s functionality during short-term outages.

- Generator: Install a generator to supply continuous power, ensuring uninterrupted operation of the Hydraloop in the event of prolonged power cuts.

- Selective Water Usage: If multiple toilets are in use, designate one toilet to be supplied by tap water during a power outage.

- Backup Bypass to Tap Water: Implement a backup bypass system connecting the device to tap water as an alternative water source during power outages.

Water Hardness

Before installation, please check the water hardness level of the water supplied by your water utility. If the water in your region exceeds 120–180 mg/L (ppm, or parts per million) or 7 gpg (grains per gallon), we recommend installing a water softener and/or to ensure regular maintenance for scale removal. Descaling is part of the scheduled maintenance program. Your Hydraloop installer can add citric acid to the shower drain, which enters the Hydraloop device. The device then runs an internal cleaning cycle, descaling all essential components.

Water Hardness Scale

| mg/L & ppm (parts per million) | gpg (grains per gallon) | Classification |

|---|---|---|

| Less than 17.1 | Less than 1 | Soft |

| 17.1 – 60 | 1 – 3.5 | Slightly Hard |

| 60 – 120 | 3.5 – 7 | Moderately Hard |

| 120 – 180 | 7 – 10 | Hard |

Lift Pump Requirements #

If gravity is not sufficient to move greywater to the Hydraloop device inlet, we advise installing a lift pump. A lift pump might also be necessary to remove wastewater from the Hydraloop device’s waste stream, depending on the device’s location within the building.

Install a lift pump in these 2 situations

1. To lift greywater and/or condensation water from the same floor or below the inlet of the Hydraloop device. For example, the Hydraloop device is placed on the first floor, and the shower and washing machine are on the ground floor. The lift pump will pump the greywater up to the inlet of the device.

2. If the Hydraloop device is placed in a basement without a gravity-fed sewer,. In that case, install a lift pump to pump wastewater up to the sewer line.

Lift pump considerations

- Control: Hydraloop devices are equipped with a power outlet at the back of the device for controlling the lift pump

- Ventilation: ensure proper two-way ventilation for the lift pump by installing a ventilation stack that leads outside or by creating a relief line/overflow to the sewage.

- Maximum flow: choose a lift pump that is locally available and has a maximum flow of 100 LPM/27 USGPM

Advised Models

- DAB NovaBox 30/300 (230V)

- Saniflo Sanivite (110V)

- Liberty 405 Pump (110V, CSA-certified)

Booster Pump #

If the required height or distance for transporting reusable water surpasses what the built-in distribution pump in the Hydraloop Cascade or the internal booster pump in the Polisher can handle, we advise the installation of an additional booster pump. Choose the specifications for this booster pump based on the requirements of the building.

WATER LINES BEFORE INSTALLATION #

After the plumbing is set up for greywater recycling and is ‘Recycle Ready,’ you can switch the 3-way greywater selector to bypass mode. This will enable an alternative water supply to feed toilets and/or the washing machine until the Hydraloop device is delivered and set up.

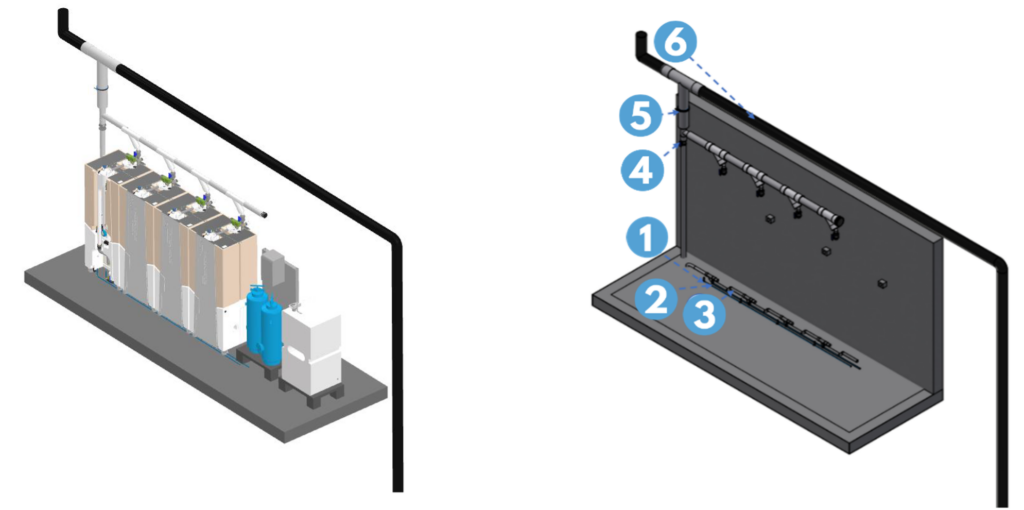

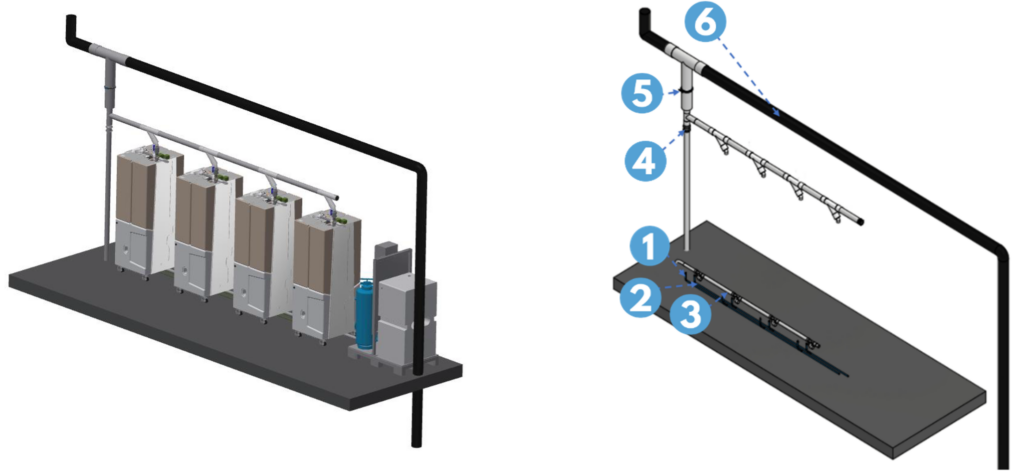

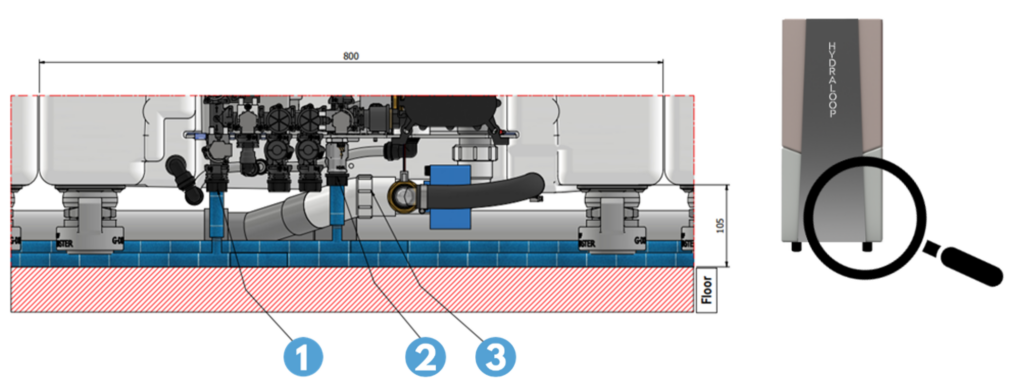

Side by side set-up

Back to back set-up

| 1 | Auxiliary outlet Reusable water, connect with flexible hose provided |

| 2 | Backup water With set-up 0 or A this is tap water. With set-up B and C, also provided by Polisher |

| 3 | Wastewater to sewer 50-75mm | 2 – 3” sewer connection with rubber gasket provided |

| 4 | Ball valve for maintenance |

| 5 | Butterfly valve For controlling the water flow |

| 6 | Main sewage pipeline |

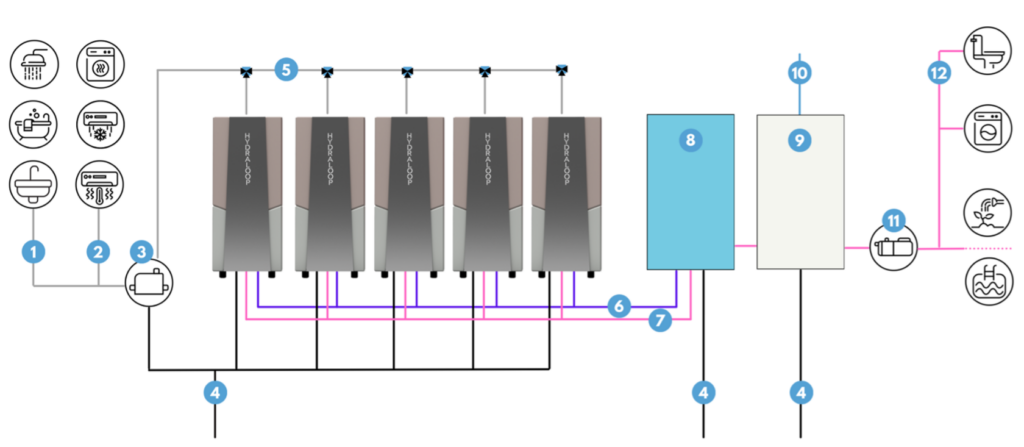

CONNECTION OVERVIEW #

| 1 | Greywater supply for water from shower, bath and hand basin |

| 2 | Condensation water supply for water from tumble dryer, air conditioning and heat pump |

| 3 | Lift pump |

| 4 | Sewer |

| 5 | Manifold |

| 6 | Cascade treated reusable water from AUX output |

| 7 | Polisher post-treated reusable water as back-up water only applicable with set-up B and C |

| 8 | Polisher |

| 9 | Buffer tank |

| 10 | Backup water |

| 11 | Booster pump |

| 12 | Dedicated pipelines for reusable water output toilet flushing, washing machine, garden irrigation or swimming pool top-up (with auxiliary outlet) |

TECHNICAL DRAWINGS #

Front view of H300 and H600

Side view of H300

Side view of H600

| 1 | Auxiliary outlet Reusable water: connect with flexible hose provided |

| 2 | Backup water With set-up 0 or A this is tap water. With set-up B and C, also provided by Polisher |

| 3 | Wastewater to sewer 50-75mm | 2-3” sewer connection with rubber gasket provided |

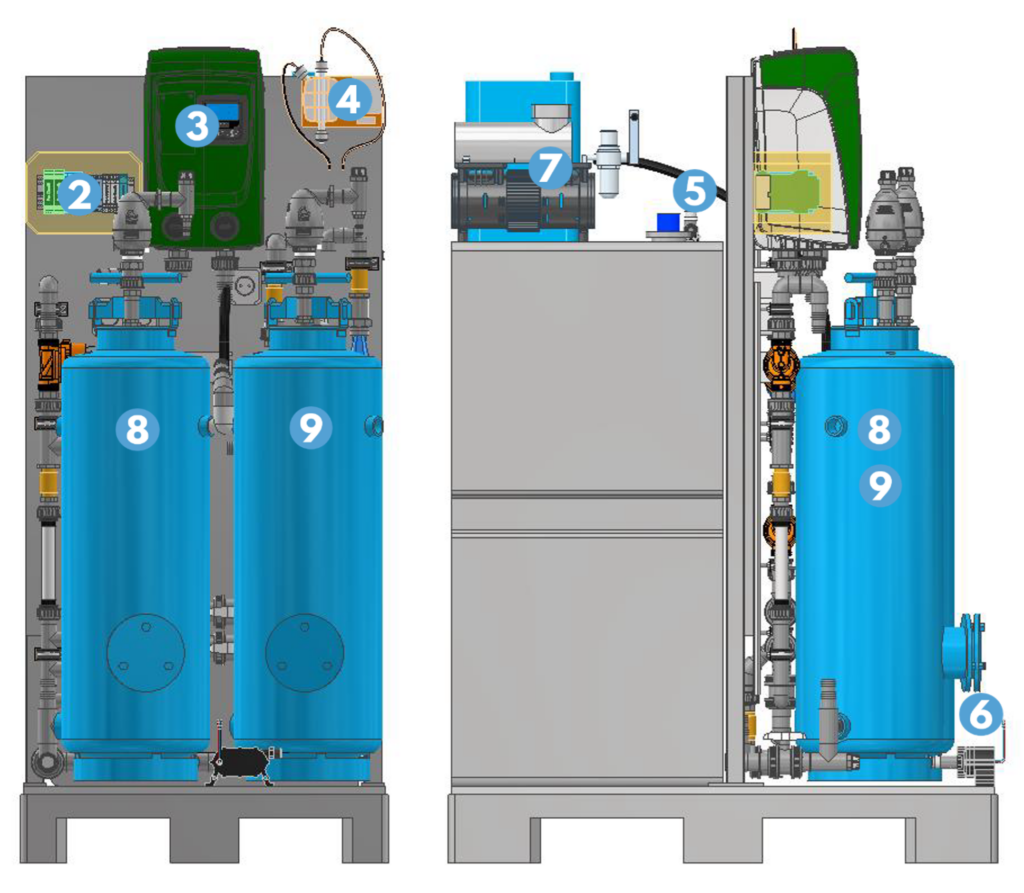

POLISHER COMPONENT OVERVIEW #

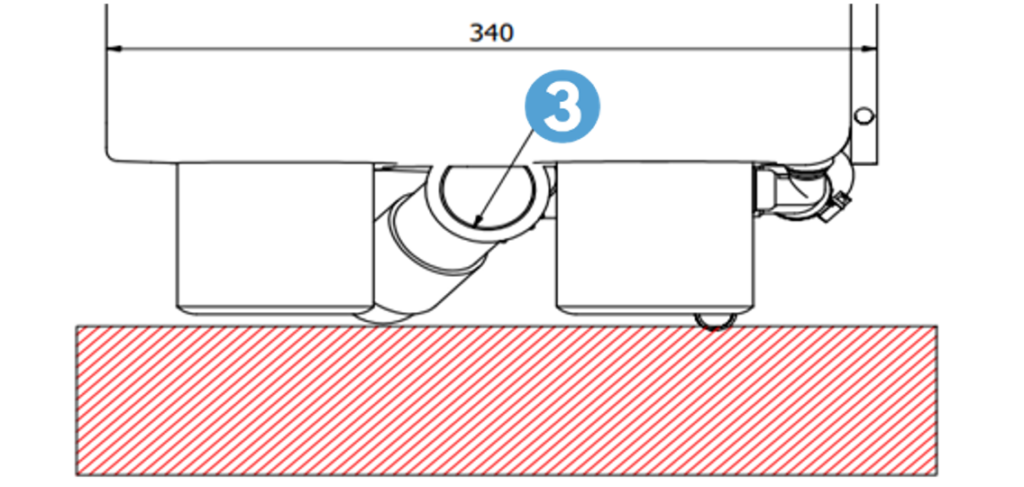

Set-up A – Residual Disinfection #

| 1 | Buffer tank |

| 2 | Water pump |

| 3 | Dosing pump |

| 4 | Back-up water supply |

| 5 | Water meter |

| 6 | Chloride tank |

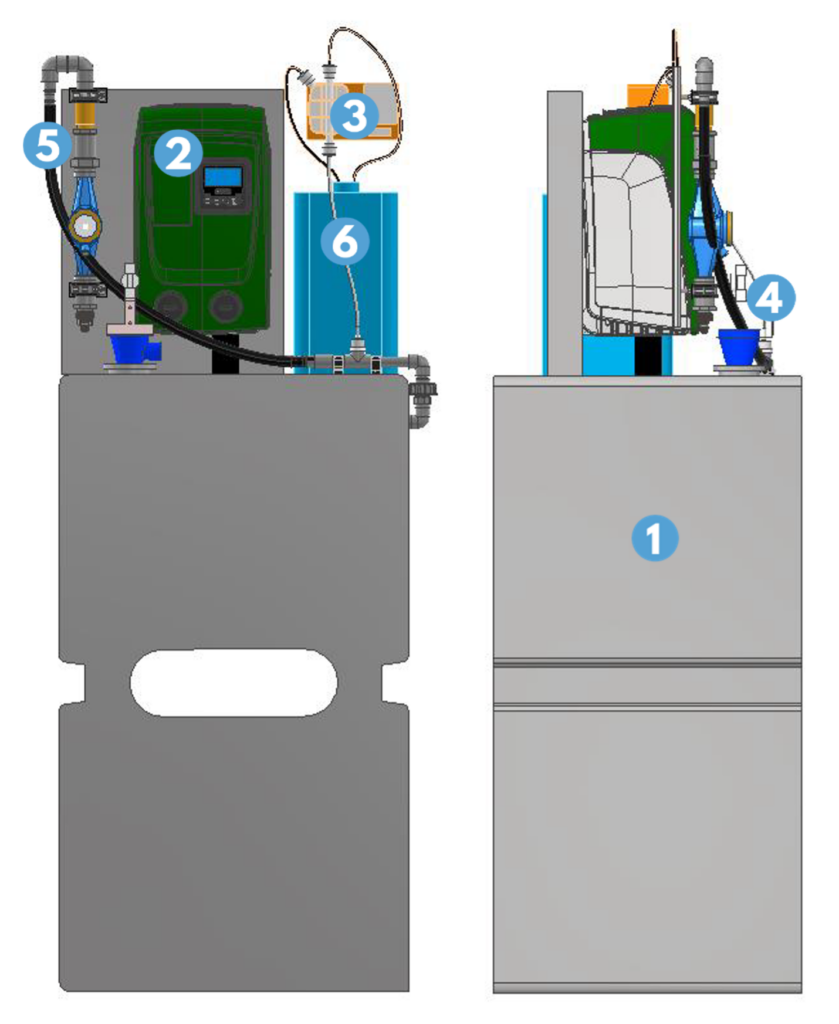

Set-up B – Residual Disinfection and Sand Filter #

| 1 | Buffer tank |

| 2 | Electrical cabinet |

| 3 | Water pump |

| 4 | Dosing pump |

| 5 | Back-up water supply |

| 6 | Circulation pump |

| 7 | Compressor |

| 8 | Sand filter |

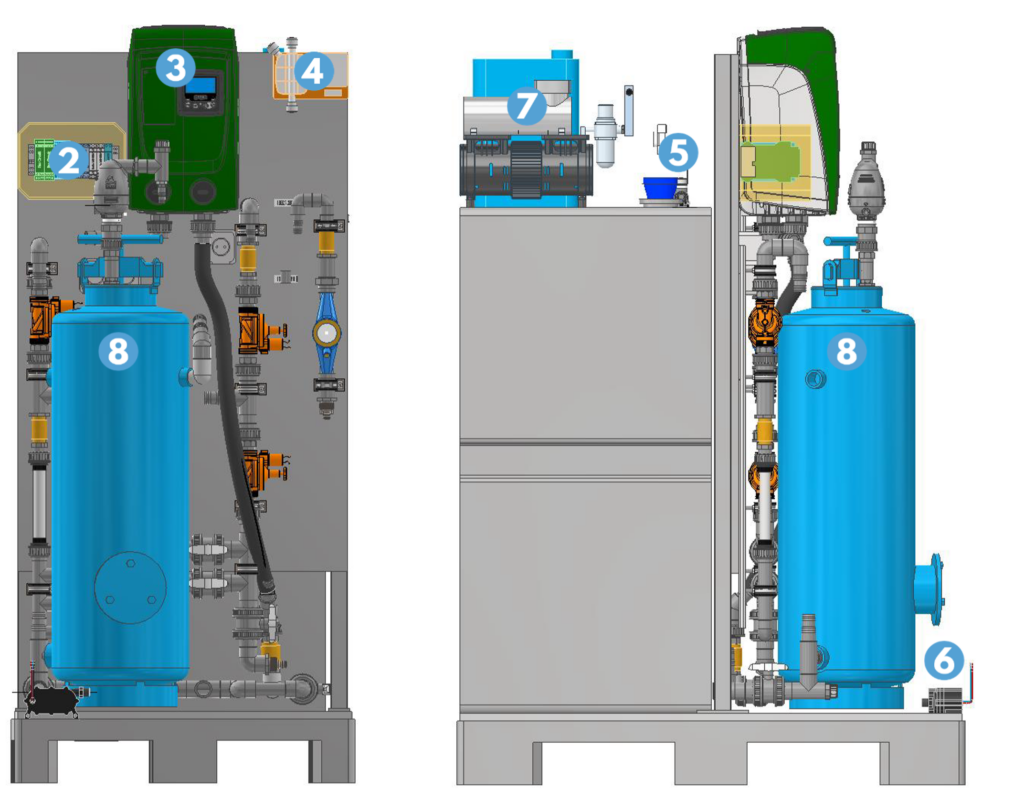

Set-up C – Residual Disinfection, Sand Filter and Activated Carbon Filter #

| 1 | Buffer tank |

| 2 | Electrical cabinet |

| 3 | Water pump |

| 4 | Dosing pump |

| 5 | Back-up water supply |

| 6 | Circulation pump |

| 7 | Compressor |

| 8 | Sand filter |

| 9 | Activated Carbon Filter |

SYSTEM SPECIFICATIONS #

| Hydraloop H300 | |

|---|---|

| Volume | 300 liters | 80 gallons |

| Cleaning capacity | 360 liters | 95 gallons per day depending on user behavior |

| Voltage | 100 / 240V, 24V internal |

| Average power consumption | 220 kWh/year, 25W during treatment |

| WiFi | The Hydraloop device needs to be connected with an internal 2.4 GHz WiFi-network or ethernet cable. Wi-Fi Protocols: 802.11 b/g/n Security: WPA/WPA2/WPA3-Personal, WPA2-Enterprise Network protocols: IPv4, IPv6, SSL, TCP/UDP/HTTP/FTP/MQTT |

| Noise Level | ± 44 dB |

| Greywater input sources | – shower – bath – washing machine (with inlet diverter) |

| Hydraloop H600 | |

|---|---|

| Volume | 600 liters | 160 gallons |

| Cleaning capacity | 850 liters | 225 gallons per day depending on user behavior |

| Voltage | 100 / 240V, 24V internal |

| Average power consumption | 460 kWh/year, 53W during treatment |

| WiFi | The Hydraloop device needs to be connected with an internal 2.4 GHz WiFi-network or ethernet cable. Wi-Fi Protocols: 802.11 b/g/n Security: WPA/WPA2/WPA3-Personal, WPA2-Enterprise Network protocols: IPv4, IPv6, SSL, TCP/UDP/HTTP/FTP/MQTT |

| Noise Level | ± 46 dB |

| Greywater input sources | – shower – bath – tumble dryer – air conditioning – heat pump – washing machine (with inlet diverter) |

| Hydraloop Polisher | |

|---|---|

| Dimensions | Height: 1800 mm | 70.9” Width: 800 mm | 31.5” Length: 600 mm | 23.6” |

| Cleaning capacity | 1700-8500 liters | 225-2250 gallons per day depending on Cascade size (2–10) |

| Voltage | 100 / 240V, 24V internal |

| Frequency | 50/60 Hz |

| Peak power consumption | 1200W |

| Normal state power consumption | 100W |

| Internet | WiFi or UTP |

| Input water source | Hydraloop AUX connection only |

| Input water temperature | 10–30 °C | 50–86 °F |

| Noise Level | ± 48 dB |

| Filtration technique | Sand/GAC* |

| Sand filter volume weight | 50 kg |

| GAC* filter volume weight | 20 kg |

| Sand mesh size | 0.4 – 0.8 mm |

| GAC* mesh size | 0.80 – 1.0 mm |

| Residual disinfection technique | Solenoid dosing pump (0.375 ml/pulse) |

| Disinfectant | Hypochlorite 12,5% |

| Dosing (programmable) | Standard 2ppm (= 0.2 mg/L) |

| Standard output pressure | 3 bar |

| Standard output flow | 60 L/min |

* Granulated Activated Carbon

GLOSSARY OF TERMS #

Auxiliary Outlet

This valve allows for the distribution of reusable water to be used for the garden, irrigation, or pool top-up (depending on your region). This outlet is non-pressurized.

Backup water

Water that is used as a main source of water in the building. This could be tap water, municipal water, well water, rain water etc. Another term for backup water is ‘mains water’.

Blackwater

Contaminated wastewater containing pathogens from human waste and other organic materials. This waste stream can come from toilets, bidets, hand showers, floor drains, dishwashers, and kitchen sinks.

Greywater

Lightly contaminated domestic water from the drains of baths, showers and washing machines.

Hydraloop APP

This is an APP that device owners can download on their smartphone. The APP monitors how a Hydraloop device is functioning, offers tips on how to save more water and gives encouragement when water savings in the building are at a high level. The APP will notify the owner when the 21-day Activation date (and a minimum of 20 showers/baths) has been reached and when the device is ready to distribute reusable water.

Hydraloop Device Manager (HDM)

Online monitoring system for the Hydraloop device. During installation, this platform is used for testing, verification, and activation of the Hydraloop device. After installation, the HDM is used for monitoring, maintenance, troubleshooting and ticket generation. Before installation of a Hydraloop device, the HDM requires login credentials, provided by Hydraloop. Please ask your Hydraloop installer if your device has a viable login-code before installation.

Inlet diverter

This optional valve allows for the intake of greywater from sources other than the shower/bath i.e. the washing machine. By adding this valve to the inlet of the Hydraloop device, greywater from the washing machine can be treated for reuse.

Recycle Ready Guide

This is a guide provided by Hydraloop, aimed at device owners, plumbers, and contractors. The Recycle Ready Guide explains how to prepare and configure the plumbing network in a building, so it is ready to receive and recycle greywater.

Recycle Ready Checklist

Once preparations are complete, the Hydraloop owner and construction professional verify and co-sign the ‘Recycle Ready Checklist’. Then, the Hydraloop owner sends the co-signed Checklist to their Hydraloop Partner. Without a signed and verified Recycle Ready Checklist, an installation date cannot be planned.

Reusable water

Greywater that has undergone various steps of treatment to be reused for toilet flushing, water for the washing machine and/or outdoor uses (irrigation, pool top-up).

Start-up Time

The Hydraloop device requires a minimum of 21 days (3 weeks) or 20 showers to develop the biological treatment process in the T2 tanks and become fully operational. If the device has not sensed 20 showers by 21 days of operation, the start-up time will last longer.

Ventilation

This is placed along the greywater line to prevent anti-siphoning of water out of airlock. Ensure that the greywater input and sewage output both have proper two-way ventilation. Ventilation for greywater input should be above all greywater lines and end outside the building.