When the valve of the T1 tank is not opening properly, the Hydraloop can not throw away water out of the system fast enough to keep itself clean.

Location of the T1 waste valve

The valve is located in the distribution center behind all other parts. See below photos.

Waste valve T1T2 not working VS Waste valve wasting too slow

There is a big difference in this problem between a valve that can not open at all, and the valve is emptying the tank too slow. Typically it only takes a few minutes to empty the tanks. Does the tank take significantly longer, the ticket gets created.

To be able to see if the tanks are emptying too slow, it is possible to look at the HDM. See the image below. Look at the orange (T2) and green (T1) graph. You can see an example of a Hydraloop where the water empties too slow to do its job properly. It took 12 minutes of the waste valve being open before T2 emptied. In this case something must be slowing down the water exiting the system. It is more normal on a full T2 tank to see max 5 minutes. These tanks weren’t even half full.

Sewage/lift pump VS internal problems

You can also narrow down the problem being part of the sewage/lift pump by trying to empty T3 instead of T1T2. If T3 is also not able to empty, the problem is most likely something with the sewage/lift pump. Use the “Maintenance” routine “Empty T3” and see if the T3 tank in the graph drops in value. Please note that values below 70 of T3, it MIGHT mean the T3 tank is already empty. So fill the tank again with the “Maintenance” routine “Fill T3 with backup water”. Below image shows where to look when running the “Empty T3” routine for the value dropping.

Cause #

Lift pump after Hydraloop not working (slow flow OR no flow)

Problem

If after the installation of the Hydraloop a lift pump is used to throw away water to the sewer, this pump can be malfunctioning. When the pump is not able to pump, the Hydraloop is unable to get the water out of the system.

First off, you can confirm if a lift pump is installed after the Hydraloop by going to the HDM. Then on the “Device” tab of the system (scroll a bit down), there is this ‘checkbox’. If filled in correctly during installation, you can see if there is a “Lift pump after (device -> sewer)” installed. See image below

Solution

Inspect the lift pump. Lift pumps often need periodic maintenance/cleaning. It could be that the pump got ‘clogged’. Clean it to solve the problem. Then test it by running the HDM “Maintenance” routine “Empty T1/T2”

Debris stuck in T1 U-bend (slow flow OR no flow)

Problem

Often after construction or renovation building materials are thrown in the drain. This causes the U-bend PVC piping protecting the T1 waste valve to become clogged (see below picture of the U-bend). Even though the valve is still working. Water is unable to move out of the tank anymore.

Solution

Please contact Hydraloop support to get rid of most water from the system and instructions to unclog.

Loose wire ‘T1 waste valve’ (no flow)

Problem

This will have the same effect as a broken valve. Often this loose wire is caused by the connector between the component and the wire not being secured well. These wires make contact with each other through metal. And if the metal does not touch each other anymore, no electricity can flow anymore to control the valve.

Inspect the wires. Using a multi meter can be handy to decide if the wires are even connected well if a visual inspection is not enough. Measure resistance between the two ends of the connector over 1 wire and repeat on the other side. Or even better. Measure if the wires receive 24 volt over the wires when running the HDM “Maintenance” routine “Empty T1/T2”. During this routine the valve should be getting powered.

Solution

Try to fix the cabling. Or replace the cabling for new cables.

Then run the HDM “Maintenance” routine “Empty T1/T2”. During this routine the valve should open. And the T1/T2 tanks in the HDM graph should lower.

The ‘T1 waste valve’ stopped working OR opening halfway (slow flow OR no flow)

Problem

This failure could be caused by:

- Wear and tear

- Debris entered the valve assembly and damaged the valve

- Calcium buildup could get the valve stuck. This only happens if the system dries up. The valve should be under normal operation always wet.

Solution

Please contact Hydraloop support to get rid of most water from the system and instructions to replace the valve.

Sewer obstructed/clogged after Hydraloop (slow flow OR no flow)

Problem

If none of the above seem to be the cause of the problem. It is time to start looking into any potential obstruction/clogging beyond the Hydraloop.

It could be that the venting system of the sewage is malfunctioning/obstructed. If the sewage has no way for air to be pushed out or in, then the water will flow a lot slower. As any vacuum holds the water in place. And any increase in air would mean the air has to be pushed away too. You would see this in the HDM graph of emptying T1/T2 as ‘slow flow’.

Or a ‘water trap’ / ‘U-bend’ is preventing any open air connection to help the water be thrown away.

It could also be that debris is blocking the path of the water from flowing. Either completely blocking it, or slowing the flow.

Solution

Please contact the house plumbers for solving this problem. Inspect venting lines of the house. Or use a de-clogging tool in the sewer line AFTER the Hydraloop. Really make sure to not do it before the Hydraloop installation.

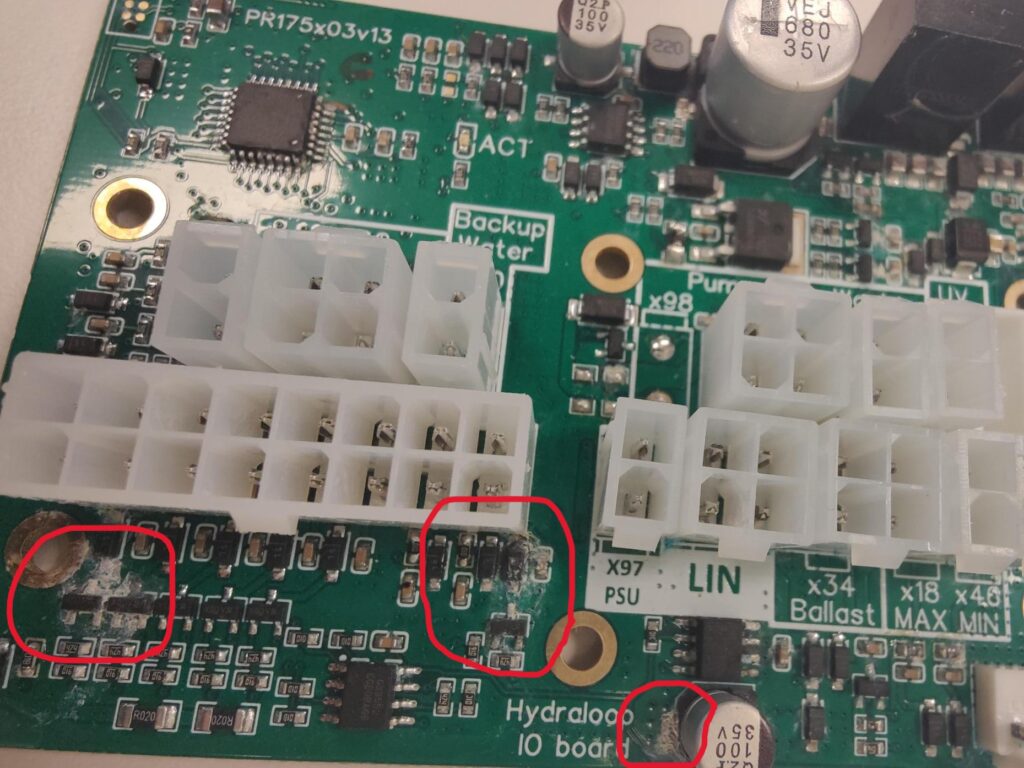

IO-board (water) damage

Problem

The IO-board that controls the Hydraloop can also be damaged. Often the damage manifests as valves or other components constantly being powered. Or not powering at all. The damage could be clearly visible (see below image of clear calcium marks from dried up water). But often it is not that easy to see.

Solution

Replacing the IO-board is the only thing that would solve this problem.