SAFETY #

GENERAL SAFETY INSTRUCTIONS #

WARNING

- Read this manual before installing and/or operating your Hydraloop device.

- The Hydraloop device produces NON-POTABLE water. DO NOT use the Hydraloop device output water for potable use. Please note that the backup water outlet and non-potable outlet are close in proximity.

- The device should only be opened or serviced by Hydraloop staff or certified Hydraloop partner and/or installers. Risk of electric shock may occur.

- The Hydraloop device should be installed according to installation manual for safe operation.

WARNING

- A damaged power cable should always be replaced by Hydraloop staff or certified Hydraloop partner and/or installers.

- Always disconnect the Hydraloop device from backup water supply before servicing or performing maintenance.

ATTENTION

- Following commissioning and/or work on the Hydraloop device, lines should always be checked for leaks and potential cross connection.

RECOMMENDATIONS #

ATTENTION

- The Hydraloop device should only be installed indoors with an ambient temperature between 14-35°C | 57-95°F.

- The Hydraloop device should never be exposed to sunlight.

- Reusable water should never be connected to a bidet and/or a toilet hand-shower.

- The Hydraloop device should always be accessible for service and maintenance.

ATTENTION

- The Hydraloop device should only be moved or transported in an upright, vertical position.

- Care should be taken not to damage the exposed underside of the device.

ATTENTION

- Never direct greywater from kitchen sinks, floor drains or dishwasher to the Hydraloop device.

- Only use greywater from shower/bath, and optionally from washing machines.

- In cases of excessive soap use, foam may form within the Hydraloop device.

RESPONSIBILITY AND LIABILITY #

MANUFACTURER #

Hydraloop guarantees the proper working of the device according to its general sales conditions.

As a manufacturer, Hydraloop is not liable in the following cases:

- Failure to follow instructions for Recycle Ready preparation, installation, maintenance, and/or operation of the device

- Inadequate or insufficient maintenance of the device

INSTALLER #

The installer is responsible for the installation and activation of the Hydraloop device:

- Installation shall be according to local legislation, electrical and plumbing codes

- Installer must have obtained login details from Hydraloop Sales Engineer

- Testing and activation via the HDM and all necessary checks

- Maintain commissioning report and record of maintenance within their log

- Explanation of operation as well as the Hydraloop APP to the user/owner.

USER #

To ensure optimal functioning of the Hydraloop device, please observe the following:

- Owner’s manual

- The assistance of an approved, trained, and qualified installer for Preparation, Installation, Testing, Verification, Activation, and regularly scheduled maintenance of the device

- Regular maintenance is required in which the interval is subject to the quality of the input water

- The operation of the Hydraloop APP

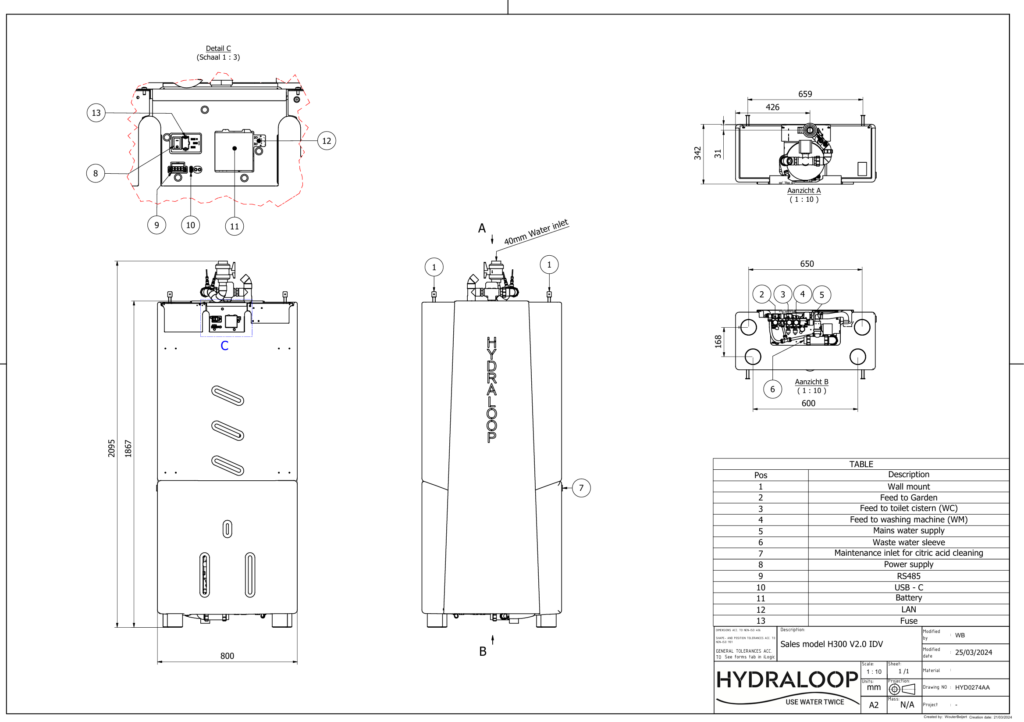

HYDRALOOP H300 DIMENSIONS AND WEIGHTS #

| HYDRALOOP MODEL | WIDTH (MM) | DEPTH (MM) | HEIGHT (MM) | DRY WEIGHT (KG) | WET WEIGHT (KG) |

| H300 (Inlet standard) | 800 | 335 | 2095 | 82,5 | 383 |

| H300 (Inlet Diverter) | 800 | 335 | 2095 | ||

| H300 PACKAGED | 815 | 800 | 2198 | 90,5 | – |

| H300 DISPLAY MODEL | 810 | 335 | 2045 | 40 | – |

| H300 DISPLAY MODEL PACKAGED | 815 | 345 | 2198 | 50 | – |

| HYDRALOOP MODEL | WIDTH (INCHES) | DEPTH (INCHES) | HEIGHT (INCHES) | DRY WEIGHT (POUNDS) | WET WEIGHT (POUNDS) |

| H300 (Inlet Standard) | 31.49 | 13.19 | 82.48 | 181.91 | 844.52 |

| H300 (Inlet Diverter) | 31.49 | 13.19 | 82.48 | ||

| H300 PACKAGED | 32.08 | 31.50 | 86.54 | 199.55 | – |

| H300 DISPLAY MODEL | 31.88 | 13.19 | 80.51 | 88.20 | – |

| H300 DISPLAY MODEL PACKAGED | 32.08 | 13.58 | 86.54 | 110.25 | – |

OFF-LOADING AND UNPACKING INSTRUCTIONS #

The Hydraloop device will be transported to your location mounted and strapped onto a HL-Transport plate, wrapped in protective packaging, and mounted onto a wooden pallet.

- When moving the Hydraloop device, it is important to always keep it in an upright, vertical position. A horizontal position may cause damage to the devices’ internal components and seals.

- Leave the protective packaging on the device until it is placed at its final installation position.

- Once the device is taken off its wooden pallet, leave it strapped to the wooden transportation plate. It can then be moved with a 2-wheel trolley.

- Only when it is near its final position do you remove the packaging and carefully lift the device from the plate.

*NOTE: Please do not remove the Hydraloop device from transportation plate until it has reached its final location. Do not use any apparatus underneath the device to move it as this will cause damage to the exposed underside.

a – edge protection

b – H: with skid: 218cm | 86”

c – H: without skid: 189cm| 74”

d – L: 82 cm| 32”

e – W: 35 cm | 14”

Dry Weight: 92 kg | 203 lbs

Wet Weight: 382 kg | 846 lbs

The H300 1.5 device comes with the following items:

– H300 1.5 device

– ½” gasket (6x)

– PVC ball valve

– Power cable

– Mesh inline filter

– Flexible connectors (3 ×)

– Steel square shoulder square for mounting

– Quick Reference Guide

INSTALLATION CONSIDERATIONS #

Basic installation steps

- Prior to installation ensure that you are following applicable plumbing and electrical guidelines in your city or state/province and that your plumbing configuration is protected against backflow and cross connection maintaining the safety of the public water supply.

- Position the Hydraloop device in its planned location.

- Connect H300 1.5 wastewater outlet to sewer.

- Connect incoming greywater to the inlet on the top of the device via inlet manifold, in combination with external lift pump if necessary.

- Connect H300 1.5 reusable water outlet connections.

- Connect the backup water supply and open.

- Plug 100/240V power cord into wall socket.

- Run the Testing, Verification and Activation using the HDM with your Hydraloop Sales Engineer.

H300 1.5 INSTALLATION ORIENTATION #

The H300 1.5 device is to be installed against the wall, leaving room for the electrical connection. The device must be secured to the wall to protect against falling over. The top plate comes equipped with a mounting hole for fastening to the wall.

Hook the mounting hole of the H300 1.5 top plate onto the square shoulder hook, which is drilled and fasten into the wall, so the Hydraloop device is fixed to the wall and protected against falling over.

FRONT PLATE REMOVAL #

To remove the stainless-steel front plate, use a lever on the lower side of the front plate to carefully lift the stainless plate upwards. The plate is holding its position due to its shape so once it moves upwards it will be free to remove. Disconnect the LED light connection from the front plate and put the plate aside.

- Carefully wedge a wooden (broom stick handle) or plastic tool between the bottom of the front plate and the floor and move the front plate upwards.

- Remove the front plate off the device.

- Disconnect the earth wire and LED light connection (Premium model) from the top of the front plate being careful not to break the wire connection.

- *Place the front plate in a way that the front plate cannot fall and be damaged.

H300 1.5 greywater inlet installation #

- Blue sealing ring

- Greywater inlet

- Incoming water sensor

- Incoming water sensor

- Ventilation valve

Install the H300 1.5 inlet manifold as follows: #

1. Take the grey inlet manifold (40 mm/1 1/2” OD), and carefully install it into the top inlet of the T1 tank.

2. The supplied blue rubber plug needs to be slid over the grey inlet pipe to just below the first elbow of the pipe.

3. Lubricant (Vaseline) must be applied to the blue rubber plug and the T1 tank inlet.

4. The inlet pipe can then be pushed all the way into the T1 tank, ensuring a watertight seal is made. The pipework inlet should now be facing the back wall.

5. Using lubrication, the 12 mm | 15/32” grey air pipe can then be connected to the grommet on the ventilation valve elbow of the inlet manifold.

6. The solid blue and see-through blue air pressure sensors can be connected to the appropriate sensor ports on the top of the inlet manifold.

7. You can now connect the greywater feed line from Recycle Ready 3-way valve to the manifold inlet.

8. Once all the above steps are complete, please ensure that all pipes and connections are watertight and secure with no leaks.

REUSABLE WATER OUTLETS #

The Hydraloop device comes equipped with two standard outlet valves, (1) dedicated for feeding multiple toilets (no high flush toilets) and (1) dedicated for feeding one washing machine. There is also an optional auxiliary outlet valve that can be added to feed the garden/pool.

Note that the irrigation valve will not be permanently pressurized. Unlike the other two reusable water outlets, this outlet’s standard function is to supply reusable water when a surplus is available.

Note the outlet connections on the Hydraloop device in the drawings below:

| Connection specifications Hydraloop H300 1.5 | |||||

| Input connection | Size (imperial) | Size (metric) | Thread type | Additional information | |

| Greywater supply (top of Hydraloop) | 1 ½” | 40 mm (OD) | PVC | Into feed channel | |

| 1. | Backup water supply | ½” | 15 mm | male | Determine incoming water pressure – 12 lpm| 3 GPM – if over 4 bar floater cap & flow regular must be installed on T4 manifold |

| 2. | Inline strainer | 1 ½” | 40 mm (OD) | male | |

| Inlet diverter (optional) | 1.57” | 40 mm (OD) | PVC | ||

| Output connection | Size (imperial) | Size (metric) | Thread type | Additional information | |

| 3. | Auxiliary outlet: non-potable | ½” | 15 mm | male | Connect to flexible hose |

| 4. | Toilet supply: non-potable | ½” | 15 mm | male | Connect to flexible hose |

| 5. | Washing machine supply: non-potable | ½” | 15 mm | male | Connect to flexible hose |

| 6. | Wastewater line | 1 ½” | 40 mm (OD) | PVC | *Into rubber sleeve – 40 mm ID or 40/50 adapter |

H300 1.5 WASTEWATER OUTLET INSTALLATION #

The 40 mm |1 1/2″ OD wastewater line at the bottom of the H300 1.5 needs to be connected to the sewer with the PVC eccentric adapter ring or *rubber reducing sleeve (40 mm ID or 40/50) through the floor (first image) or backwards into the wall (second image). Please note that the rubber reducing sleeve do not come with the Hydraloop device and must be provided by the installer. \

*Rubber reducing sleeve – 40 mm ID or 40/50 rubber adapter: OR equivalent available in your country –

Not included with the Hydraloop device

Option #1:

H300 1.5 drain line connected to sewer system by using reducing sleeve

Option #2:

H300 1.5 drain line connected to sewer system through the back wall.

INTRODUCING AN EXTERNAL LIFT PUMP #

If the Hydraloop device is on the same or higher floor as the shower/bath or washing machine an external lift pump needs to be incorporated to have the source greywater enter the device.

To discuss alternate options for introducing an external lift pump please refer to your Recycle Ready document or speak to your Hydraloop Sales Engineer for assistance at support@hydraloop.com.

NOTE: When servicing the lift pump please have Hydraloop device on bypass so as not to potentially clog the device with particulate that may have accumulated in the lift pump over time.

INSTALLATION #

The Installation, Verification and Activation of the Hydraloop device should only be carried out by approved installers who have prearranged for their HDM login. This can only be done through messaging support@hydraloop.com. Once you have made your appointment you will receive authorization and your login.

The drawing below is a reference to the piping configuration that has been completed via the Recycle Ready Guide.

PREPARATION, INSTALLATION, TESTING, VERIFICATION AND ACTIVATION OF THE H300 1.5 DEVICE #

- Preparation – Recycle Ready configuration and Recycle Ready checklist must be complete and submitted to support@hydraloop.com

- Installation

- Delivering of H300 1.5 to site

- Unboxing of the device

- Placing the device in position

- Securing the device to the back wall leaving room for electrical connections

- Connection of greywater inlet, backup water and reusable water lines

- Applying electrical connection

- Testing, Verification and Activation: This step is conducted through the HDM by an approved and trained Installer with a pre-requested login to the HDM. Hydraloop Sales Engineers will be available for first time installers to assist and guide them through the process.

- Switch device from greywater bypass to the Hydraloop device

- Go through testing of all device systems via the HDM “verification”

- Select priority options connected to toilets, washing machine, auxiliary outlet, and lift pumps

- Activation of the H300 1.5 when all device systems have passed the validation steps. This will occur automatically once all HDM steps have been completed.

- Commissioning: This step will be conducted through the APP, by the client, or someone assisting the client when the client is occupying the home, and permanent Wi-Fi has been established.

- Set up permanent Wi-Fi connection through the APP. Ethernet connection is also available on the device.

- Connect the client’s smartphone to the Hydraloop device through the APP

- Fill in the Warranty information via the APP. At this point in time the Warranty period will start as well as the start-up time

Activation of the device cannot be performed until installer has registered for an HDM login.

Accessing the HDM:

- Open hdm.hydraloop.com in your browser

- Sign in with your Username and Password as supplied via email from your Hydraloop Sales Engineer

- Two-factor authentication is required, enable it to gain complete access

- Install the APP of your operating system choice

- Scan QR code

- Enter verification code

- Change your password

- Save Changes (Save icon in top right-hand corner)

Once logged into HDM you will be instructed to scan the barcode on the top of the Hydraloop device. Scanning the barcode will open your device up onto the HDM and the verification process will begin. You will be given instructions on how to proceed to the next steps.

The Hydraloop APP needs to be downloaded on both the Installers and device owners smartphone.

If you need assistance, please call your Hydraloop dealer or contact Hydraloop Sales Engineer via email support@hydraloop.com

STARTUP TIME #

The Hydraloop device requires a minimum of 21 days (3 weeks) and 20 showers to develop the biological treatment process in the T2 tanks and become fully operational. The greywater treatment will start from the initial start-up; however, this reusable water will be purged into the sewer and the backup water will be supplied instead. After this start-up period of 21 days (3 weeks) and 20 showers, the Hydraloop device will automatically switch over to deliver reusable water to the toilets, washing machine and/or auxiliary outlet.

BACKUP WATER & BACKFLOW PREVENTION #

If there is not enough reusable water available, the device will automatically switch to backup water. The device is connected to its backup water supply via an air gap to protect the tap water against backflow or cross contamination. Additionally, a non-return valve is mounted on the point of incoming backup water. NOTE: If using rainwater as a backup water supply pretreatment must be applied prior to entering the Hydraloop device. Pretreatment should include a 5-micron filter and carbon filtration, UV disinfection, expansion vessel and a pressure regulator (depending on the booster pump). The incoming flowrate should not exceed 12 lpm | 3.2 gpm, 1.5-3 bar | 21.75 – 43.5 psi.

PLUMBING BACKUP FACILITY #

During periods of unscheduled maintenance, service, or power failure it might be possible that supply of reusable water backup water is temporarily not available. To overcome this a bypass option can be installed. The bypass setup must comply with the applicable regulations of the country, state, or municipality.

DEVICE MALFUNCTION #

The Hydraloop device is extremely reliable, and all critical components are monitored continuously by our server through a permanent Wi-Fi internet connection. In the unlikely event a component fails (i.e., the UV lamp) the device will automatically switch to backup water, and everything in-house will function as usual, with no reusable water being distributed as a precaution. An automated system warning will appear on the HDM and Hydraloop APP.

Warning

Hydraloop device is designed for ‘normal usage’ and is not designed to receive solid materials like stones, chemicals, paint residues, hair dye, bleach, disinfectants, or any other matter that is unusual for shower/bath and washing machine greywater. In the event these substances enter the H300 1.5, it can be damaged, and the water treatment can be affected. There is a function in the APP where the greywater from the T1 tank can be wasted to the sewer if you suspect foreign matter has entered the Hydraloop device (i.e., hair dye or bleach).

Note: Hydraloop Systems BV is not liable for any damage if the above or any other abnormal substances enter the H300 1.5.

WARRANTY #

Under this Factory Warranty (“Warranty”) Hydraloop warrants to the first and original purchaser of the Hydraloop device set forth in Part 1 of the Warranty Policy under “Customer”, such product hereinafter referred to as the “Product”, that such Product shall be free from material Defects for a period of two (2) years as of the date of the original purchase invoice from Hydraloop or one of its authorized Partners, unless local jurisdiction requires a longer term. “Defect” as used in these warranty terms means a manufacturing or a design defect that materially impinges on the use of the Product and which is solely attributable to Hydraloop and that was not detectible at the time of delivery of the Product or part of the Product.

Installer to assist Hydraloop device owner with entering their information, contact details and physical address into the warranty section on the Hydraloop APP.

AVERAGE REUSABLE WATER QUALITY #

| NSF 350 Effluent Parameters | |

| CBOD5 | 10 ppm (mg/L) – AVG |

| TSS | 10 ppm (mg/L) -AVG |

| Turbidity | 5 NTU – AVG |

| E. coli | 14 MPN/100 mL |

| pH | 6-9 |

| Noise level | = + 44 dB |

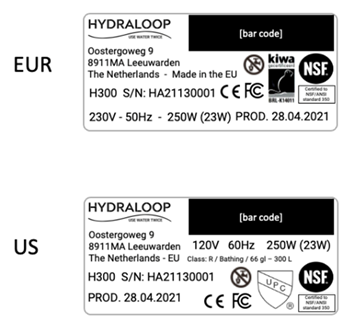

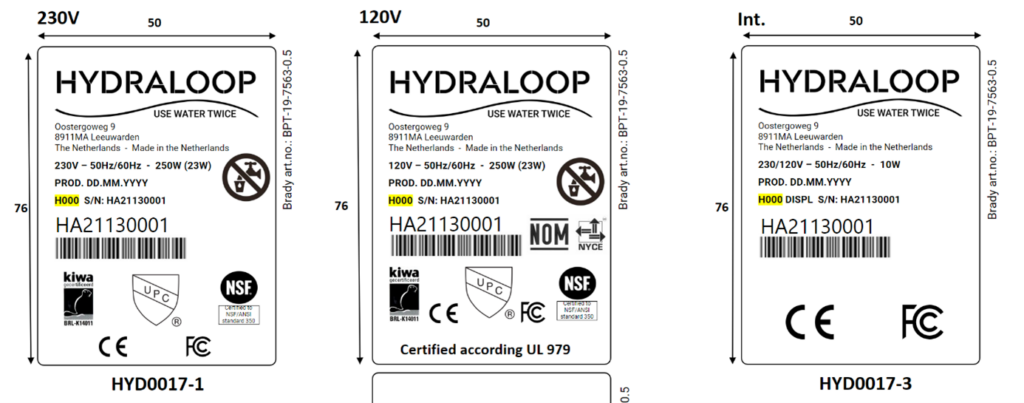

DATA PLATE / SERVICE LABEL #

The Hydraloop device has a permanent data plate attached to the top of the device that should look like the example below.

This document and its contents are the sole property of Hydraloop Systems B.V. and must not be copied to a third party, either in part or whole, without the prior written consent of Hydraloop Systems B.V.

Hydraloop reserves the right to change the specifications stated in this document.

Hydraloop products are protected by patents and patents pending. The Hydraloop brand name is a registered trademark.