RECYCLE READY GUIDE

Fill in the recycle ready checklist here

A Hydraloop greywater recycling device collects and treats greywater for non-potable use. Before the installation of a Hydraloop device, make sure that the plumbing in your building is configured as per this guide. In this 'Recycle Ready' Guide, you will find all necessary information to get any building 'Recycle Ready' (RR).

TABLE OF CONTENTS

-

Glossary

-

Owner Guidelines

-

Plumbing Guidelines

-

Colour legend

-

‘Recycle Ready' Plumbing Diagram

-

Plumbing Options

-

Connection overview

-

Physical install requirements

-

Lift Pump Specifications

-

Water Line Configuration Prior to Hydraloop Device Installation

-

Technical Drawings

-

H300 Specifications

-

H600 Specifications

GLOSSARY OF TERMS

Greywater: Lightly contaminated domestic water coming from the drains of bath, showers and washing machines.

Blackwater: Contaminated wastewater containing pathogens from human waste and other organic materials. This wastestream can come from toilets, bidets, hand showers, floor drains, dishwashers, and kitchen sinks.

Reusable water: Greywater that has undergone various steps of treatment in order to be reused for toilet flushing, water for the washing machine and/or outdoor uses (irrigation, pool top-up).

Backup water: Water that is used as a main source of water in the facility. This could be municipal water, well water, rain water etc. Another term for backup water is ‘mains water’.

Inlet diverter: This optional valve allows for the intake of greywater from sources other than the shower/bath i.e. the washing machine. By adding this valve to the inlet of the Hydraloop device, greywater from the washing machine can be treated for reuse.

Auxiliary Outlet: This valve allows for the distribution of reusable water to be used for the garden, irrigation or pool top-up (depending on your region). This outlet is non-pressurized.

HDM: Hydraloop Device Manager – online monitoring system for the Hydraloop device. Through this platform the Testing, Verification and Activation of the Hydraloop device are conducted as well as the monitoring, maintenance, troubleshooting and ticket generation. The HDM requires a login from your Hydraloop Sales Engineer in order to be activated. This login is generated by the Hydraloop Sales Engineer.

Hydraloop APP: This is an APP that device owners can download on their smartphone to monitor how their Hydraloop device is functioning, offer tips on how to save more water and give encouragement when water savings in the home is at a high level. The APP will notify user when the 21 day Activation date has been reached (and a minimum of 20 showers/baths) and when reusable water can begin to be distributed.

Start-up Time: The Hydraloop device requires a minimum of 21 days (3 weeks) or 20 showers to develop the biological treatment process in the T2 tanks and become fully operational. If by 21 days of operation 20 showers has not been sensed by the device, the start-up time will last longer than the indicated 21 days.

Ventilation: This is placed along the greywater line to prevent anti-siphoning of water out of airlock. Ensure that the greywater input and sewage output both have proper two-way ventilation. Ventilation for greywater input should be above all greywater lines and end outside the building.

Recycle Ready: This is a Hydraloop guide for configuring the plumbing in the home to be ready to receive and recycle greywater. This guide provides all the necessary information to get any building Recycle Ready.

OWNER GUIDELINES

![]() Work with professionals:

Work with professionals:

The preparation of your plumbing must be completed by a verified installer.

![]() Check your local regulations:

Check your local regulations:

Before moving forward with your installation, please check your local guidelines for recycled greywater re-use.

![]() Submit your Pre-Installation Checklist:

Submit your Pre-Installation Checklist:

Before the installation of your Hydraloop device, it is important to ensure the building is Recycle Ready and the Recycle Ready Checklist has been signed and forwarded to your Hydraloop Partner for verification. If you do not submit the checklist, we cannot verify, and therefore cannot proceed with the installation. Installer must have a prearranged login for the HDM with a Hydraloop Sales Engineer. Without this access Activation of the device cannot be performed.

PLUMBING GUIDELINES

![]() Input Connections

Input Connections

Only collect lightly contaminated greywater from shower/bath and washing machine (with optional inlet diverter). Do not connect the Hydraloop device to dishwashers, floor drains, or a kitchen sink.

![]() Output connections

Output connections

Reusable water can be reused for toilet flushing, washing machine use and/or distributed via an auxiliary outlet (garden irrigation). Do not supply bidets and/or hand showers with reusable water.

![]() Non-potable Water Identification

Non-potable Water Identification

All outputs from the Hydraloop system must be identified with a non-potable water sign.

COLOR LEGEND

RECYCLE READY PLUMBING DIAGRAM

PLUMBING OPTIONS

-

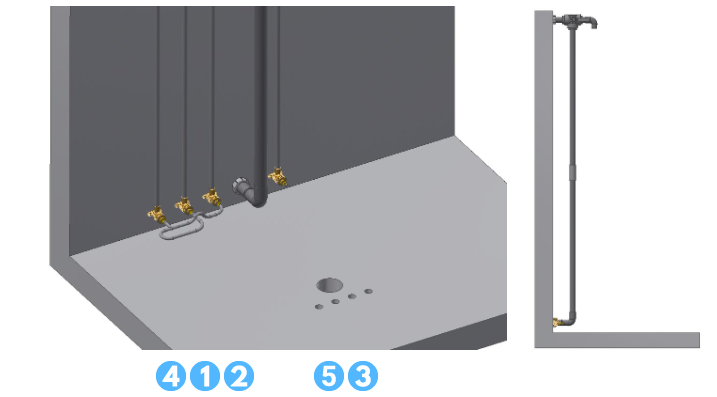

Hydraloop device on a lower floor – input by gravity

Greywater from the shower/bath or other sources is gravity fed into the Hydraloop device. -

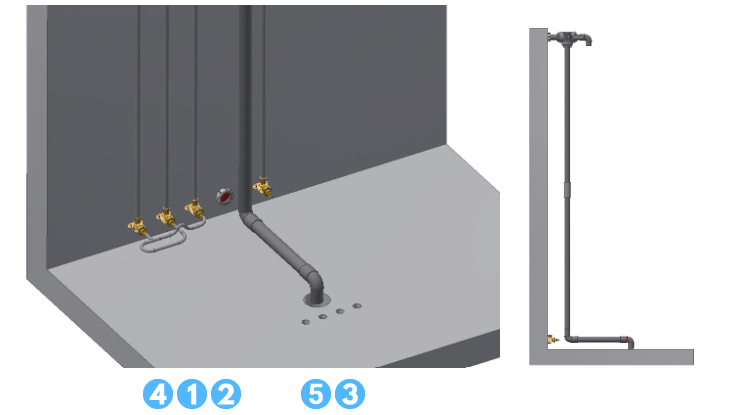

Hydraloop device on the same floor – input via lift pump

Greywater from the shower/bath or other sources enters the device through lift pump. -

Optional: Inlet diverter

50% of washing machine greywater is treated by the Hydraloop device through the Inlet Diverter.

CONNECTION OVERVIEW

Input connections

Main greywater inlet into the top of the Hydraloop device: 40 mm| 1 ½” OD

-

Bring all greywater sources into one dedicated line.

-

Please ensure all greywater lines are separated from black water.

-

If the greywater input is on a higher floor than the Hydraloop device, gravity will direct the flow.

-

In other circumstances, install a lift pump.

Greywater inlet to the Hydraloop device from

![]()

Bath

![]()

Air conditioning

Heat pump

![]()

You can connect only one (1) washing machine per Hydraloop device

Power/Network connections

![]() Permanent WiFi internet connection:

Permanent WiFi internet connection:

Bandwidth of 2.4GHz or 5 GHz

Ethernet & Bluetooth (v 2.0)

![]() Power supply: 100-120V (60Hz) or 200-240V

Power supply: 100-120V (60Hz) or 200-240V

Outlet to be within 1.2 m of device

![]() Backup water inlet

Backup water inlet

Tap water or other: 15 mm | ½” MNPT – flow of 12 LPM| 3.2 USGPM

If the flow rate is higher than 12LPM| 3.2 USGPM, floater cap and flow regulator.

If you use a rainwater pump, install an expansion vessel and 50-micron mesh pre-filter.

Output connections

![]() Wastewater outlet

Wastewater outlet

Connection to sewer: 40 mm| 1 ½” OD (min. of 50 mm| 2”) with rubber sleeve

Wastewater from the Hydraloop device to sewer (gravity) operates on a timer for wastewater release every 7 days

![]() Toilet flushing (pressurized):

Toilet flushing (pressurized):

15 mm | ½” MNPT

![]() Washing machine (pressurized):

Washing machine (pressurized):

15 mm | ½” MNPT

![]() Auxiliary outlet (non-pressurized):

Auxiliary outlet (non-pressurized):

15 mm | ½” MNPT

PHYSICAL INSTALL REQUIREMENTS

-

The greywater inlet and inlet diverter should be positioned at least 2.2m | 87” above the ground.

-

Room temperature should be between 14-35 °C | 57-95 °F. Extreme high or low temperatures should be avoided.

-

Avoid direct sunlight on the Hydraloop device. It is not IP rated or UV resistant.

-

Hydraloop recommends installing the device in a laundry room, mechanical room, or garage.

-

Allow at least 60 cm | 24” of space in front of the Hydraloop device face plate for maintenance access. The H600 has two sides that should be accessible for maintenance.

LIFT PUMP REQUIREMENTS

Please install a lift pump that is locally available and meets Hydraloop’s criteria below:

-

Max. flow of 100 LPM/27 USGPM

-

Hydraloop device is equipped with a power outlet at the back of the device for controlling the lift pump

-

Ventilation: ensure a proper two-way ventilation by installing ventilation stack that leads outside or by creating a relief line/overflow to sewage

Acceptable Models:

-

DAB NovaBox 30/300 (230V)

-

Saniflo Sanivite (110V)

-

Liberty 405 Pump (110V, CSA certified)

WATER LINE CONFIGURATION PRIOR TO HYDRALOOP DEVICE INSTALLATION

Once the plumbing configuration is Recycle Ready, the 3-way greywater selector can be set to bypass mode. This will allow the backup water to supply to the toilets and/or washing machine until the Hydraloop device has been delivered and installed.

IN THE WALL (H300 only - recommended)

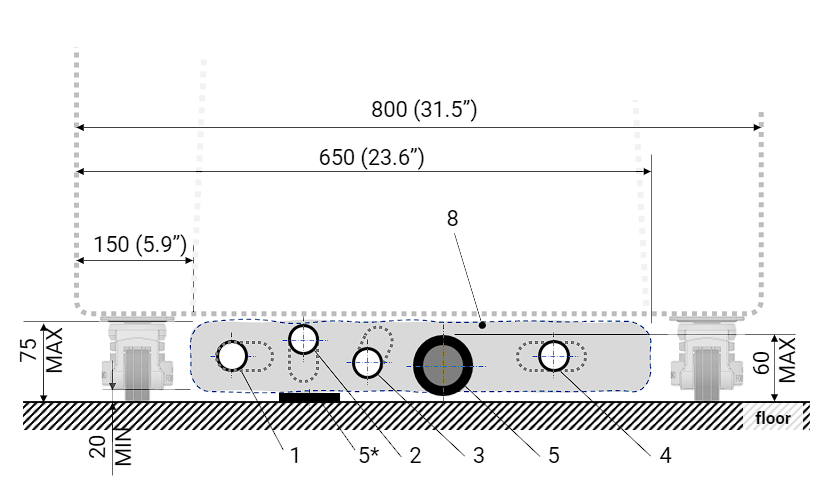

IN THE FLOOR (H300 and H600)

![]() Toilet feed

Toilet feed

Reusable water

![]() Washing machine feed

Washing machine feed

Reusable water

![]() Auxiliary outlet

Auxiliary outlet

Reusable water

![]() Backup water

Backup water

Tap water or rainwater

![]() Wastewater

Wastewater

to sewer

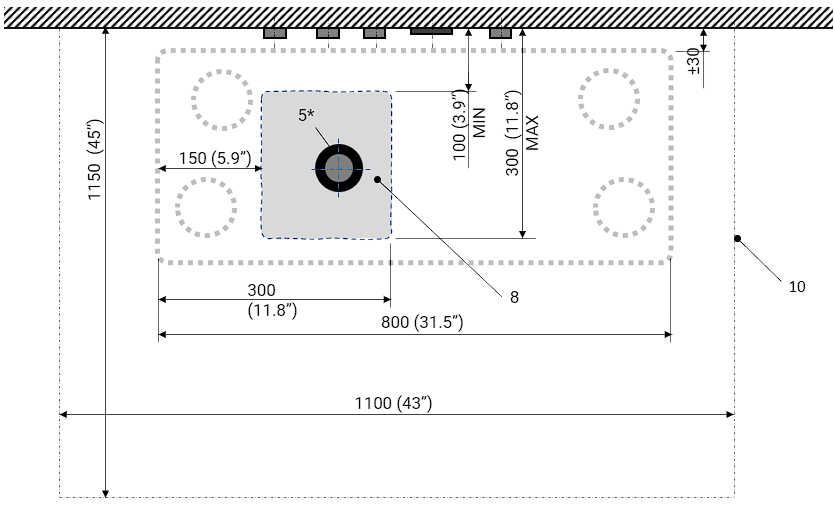

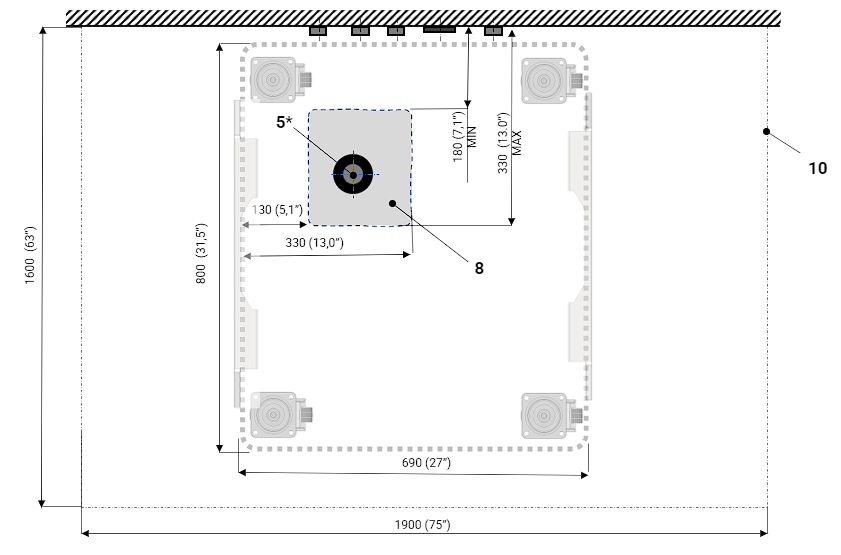

TECHNICAL DRAWINGS

Front view of H300 and H600

Top view of H300 (All dimensions in mm (inches))

Top view of H600 (All dimensions in mm (inches))

![]() Auxiliary outlet

Auxiliary outlet

Reusable water: connect with flexible hose provided

![]() Toilet feed

Toilet feed

Reusable water: connect with flexible hose provided

![]() Washing machine feed

Washing machine feed

Reusable water: connect with flexible hose provided

![]() Backup water

Backup water

Tap water and rainwater

![]() Wastewater to sewer in the wall:

Wastewater to sewer in the wall:

50-75mm | 2 – 3” sewer connection with rubber manchet

![]() * Wastewater to sewer in the floor:

* Wastewater to sewer in the floor:

50-75mm | 2 – 3” sewer connection with rubber manchet

![]() Allowed area

Allowed area

![]() Wall

Wall

SYSTEM SPECIFICATIONS

H300

Capacity

300 liters | 80 gallons

Voltage

Versions for 100-120V (60Hz)

or 200-240V (50 Hz)

24 Volt internal

Power consumption

On average: 180 kWh/yr per system

Noise Level

± 44 dB

Greywater input sources

- shower

- bath

- washing machine (inlet diverter)

H600

Capacity

600 liters | 160 gallons

Voltage

Versions for 100-120V (60Hz)

or 200-240V (50 Hz)

24 Volt internal

Power consumption

On average: 650 kWh/yr per system

Noise Level

± 44 dB

Greywater input sources

- shower

- bath

- tumble dryer

- air conditioning

- heat pump

- washing machine (inlet diverter)

Dimensions

|

HYDRALOOP MODEL |

HEIGHT (MM) |

WIDTH (MM) |

LENGTH (MM) |

DRY WEIGHT (KG) |

WET WEIGHT (KG) |

|

H300 |

2045 |

335 |

810 |

82,5 |

383 |

|

H300 PACKAGED |

2198 |

345 |

815 |

90,5 |

- |

|

H300 DISPLAY MODEL |

2045 |

335 |

810 |

40 |

- |

| H300 DISPLAY MODEL PACKAGED | 2198 | 345 | 815 | 50 | - |

|

HYDRALOOP MODEL |

HEIGHT (INCHES) |

WIDTH (INCHES) |

LENGTH (INCHES) |

DRY WEIGHT (POUNDS) |

WET WEIGHT (POUNDS) |

|

H300 |

80.51 |

13.19 |

31.88 |

181.91 |

844.52 |

|

H300 PACKAGED |

86.54 |

13.58 |

31.88 |

199.55 |

- |

|

H300 DISPLAY MODEL |

80.51 |

13.19 |

31.88 |

88.20 |

- |

|

H300 DISPLAY MODEL PACKAGED |

86.54 |

13.58 |

31.88 |

110.25 |

- |

|

HYDRALOOP MODEL |

HEIGHT (MM) |

WIDTH (MM) |

LENGTH (MM) |

DRY WEIGHT (KG) |

WET WEIGHT (KG) |

|

H600 |

2080 |

680 |

810 |

128 |

739,5 |

|

H600 PACKAGED |

2190 |

705 |

820 |

138 |

- |

|

H600 DISPLAY MODEL |

2080 |

810 |

720 |

100 |

- |

| H600 DISPLAY MODEL PACKAGED | 2190 | 705 | 820 | 72 | - |

|

HYDRALOOP MODEL |

HEIGHT (INCHES) |

WIDTH (INCHES) |

LENGTH (INCHES) |

DRY WEIGHT (POUNDS) |

WET WEIGHT (POUNDS) |

|

H600 |

81.89 |

26.77 |

31.88 |

282.24 |

1630.60 |

|

H600 PACKAGED |

86.22 |

27.76 |

32.28 |

304.29 |

- |

|

H600 DISPLAY MODEL |

81.89 |

26.77 |

31.88 |

136.71 |

- |

|

H600 DISPLAY MODEL PACKAGED |

86.22 |

27.76 |

32.28 |

158.76 |

- |